SBIR and Business issues

Generation of Human Stem Cells under Good Manufacturing Practice: Facility Update

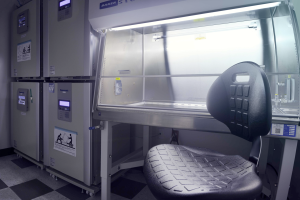

Last year Allele dedicated a new building space for cleanroom operations to provide a cell banking service for personalized medicine. This facility will be the center of current Good Manufacturing Practice (cGMP) production of human induced pluripotent stem cells (iPSCs) using Allele’s proprietary synthetic mRNA platform. Over the past three months, progress to get the facility up and running has been substantial. Our facility includes four main modules: the reception area and doctors’ offices, a Fibroblast Isolation and Maintenance room, a Reprogramming and iPSC Maintenance room, and a Quality Control room. Air handling, which is a major component of the environmental control system, has been installed and validated. Equipment such as biosafety cabinets, incubators, and refrigerators have been installed and qualified, as well as equipment for performing essential quality control steps. To standardize personnel-related steps of cGMP processing, we have prepared rigorous SOPs and have extensively trained individual manufacturing operators. Overall, we are enthusiastic about the facility’s progress and are committed to delivering the best possible service as the industry leader in iPSC banking.

……………………………………………………………………………………………………………………

cGMP Compliance: What Does It Mean for Your Cell Lines?

As the promise for cell-based therapy grows, the interest in making clinically relevant cell lines has skyrocketed for industrial and academic researchers alike. For translation into human therapies, cell-based products must be made following current Good Manufacturing Practice (cGMP). Many groups have already claimed to generate cell lines that are “cGMP-compliant,” “cGMP-ready,” or “certifiable under cGMP.” But what does it take to be truly cGMP-compliant, and what practices can you introduce in your lab to comply with cGMP standards?

A common misconception in the United States is that a facility is granted a ‘cGMP license’ from the government to manufacture cGMP-grade products. Rather, the Food and Drug Administration (FDA) evaluates the manufacturing process for each product to determine if it is compliant with cGMP standards. The primary concern when it comes to deriving cell-based products for therapies is making sure that the product is derived in a safe and reproducible manner. To ensure maximum quality assurance, researchers should

• choose reliable, xenogeneic-free raw materials,

• establish and monitor a clean environment,

• qualify all equipment and software,

• remove variation in laboratory procedures by creating detailed Standard Operating Procedures (SOPs) and by providing rigid process validation at each step.

Nevertheless, even establishing robust quality assurance does not imply that the process is scalable for commercial production. In the world of biologics, “the product is the process.” A requisite step to ensure a smooth transition to cGMP practice is to ensure that the process of manufacturing is not altered due to changes in production scale. For example, depending on the therapy, millions or billions of cells may be required for a single patient. Therefore, it is in the best interest of the researchers to develop a scalable method at the beginning to avoid revamping the entire process (e.g., changing from adherent cells to suspension). Along these lines, the quality control (QC) requirements of cell-based products should be carefully considered and not have to include difficult-to-assay tests. For example, some cell lines have been qualified as cGMP-compliant upon conversion from research-grade conditions to cGMP quality standards. Rigorous tests were performed on the converted lines to ensure that the cells were free of contamination. Even though strict measures were carried out to ensure cGMP compliancy, deriving cell lines in this manner makes scalability and reproducibility a challenge. Ideally, the entire process of deriving cell products for clinical use should be performed under cGMP conditions: from the acquisition of human tissue to the manufacturing, testing, and storage of derivative cell products.

Another important consideration when instituting cGMP-compliance is documentation. Each process must be described with rigorous SOPs, the training of individual manufacturing operators must be well-documented, and the entire established process must be validated and well noted. Failure to document—in the eyes of the FDA—is often equated with failure to perform the underlying activity. It is equally important to remain ‘current.’ The FDA expects manufacturing processes to stay up-to-date with current regulations, even as policies change.

For an academic lab, closely aligning with cGMP standards can ensure that the resulting cell lines are comparable to other truly cGMP-produced products used during clinical trials. It is in the best interest of academic researchers to establish rigorous SOPs and use qualified reagents and equipment, even if it is not possible to carry out all steps in a certified cleanroom. Whenever possible, it is advisable to acquire truly cGMP cell lines from appropriate sources for preclinical projects; if prohibited by costs or other reasons, it is recommended to use a protocol that is as close to cGMP as possible.

Press Release: Allele Biotechnology & Pharmaceuticals Closes Purchase of cGMP Facility for Production of Clinical-Grade Cells for Cell Therapy Applications

SAN DIEGO–(BUSINESS WIRE)–Allele Biotechnology & Pharmaceuticals, Inc. (“Allele”), a leader in the development of specialized cells for pharmaceutical drug discovery and regenerative medicine, today announced that it has closed the purchase of a new facility intended for its cGMP (current good manufacturing practices) production of clinical-grade cells for cell therapy applications.

The 18,000 square-foot facility, located near the main headquarters of Allele in San Diego, California, will be the center of production of human induced pluripotent stem cells (hiPSCs) using Allele’s proprietary synthetic mRNA platform, a technology that generates hiPSCs with neither the random integration of foreign DNA nor the use of whole virus or virus-based elements, drawbacks that are common to other technologies for making hiPSCs. Such “footprint-free” cells will be produced by Allele for industrial and academic partnerships, as well as Allele’s own efforts in the area of cellular therapeutics.

hiPSCs, as cells that have the potential to become any cell in the human body, hold great promise for therapies that can alleviate or cure human disease. Towards this end, Allele has recently made a number of advances regarding the differentiation of hiPSCs towards cells of specific lineages, such as neural progenitor cells, neurons, astrocytes, mesenchymal stem cells, cardiomyocytes, skeletal muscle cells, hepatocytes, and adipocytes, including brown fat cells. These cells would also be produced in the cGMP facility when intended for specific therapies.

“This dedicated facility will help us to realize a number of our visions in bringing the benefits of pluripotent stem cells to society,” said Jiwu Wang, Ph.D., President and CEO of Allele. “The first step in helping people in need with all the stem cell technologies developed in labs is to clear a path to move them from bench to bedside, which requires high-quality, controlled production that can be monitored by the FDA. Together with our licensees, drug development partners, investors, and individuals who would like to participate in banking hiPSCs for research and therapy, we anticipate even faster pace in our business development in this area.”

Contacts

Allele Biotechnology & Pharmaceuticals, Inc.

Jiwu Wang, 858-587-6645

info@allelebiotech.com

Allele’s SBIR Grant to Develop All-RNA CRISPR

Precise engineering of the genomes of mammalian cells enabled biological and medical applications researchers had dreamed of for decades. Recent developments in the stem cell field have created even more excitement for genetically modifying genomes because it enables delivering more beneficial stem cell-derived therapeutic cells to patients [1]. For instance, by correcting a gene mutation known to be critical to Parkinson’s disease, LRRK2 G2019S, in patient-specific iPSCs (induced pluripotent stem cells), it appeared possible to rescue neurodegenerative phenotypes [2].

Significant amount of fund and energy had been invested in technologies such as ZFN and TALEN, however, judging from the explosion of publications and business activities in just about 2 years since the illustration of its mechanism (just today, Jan 8th, 2015, Novartis announced CRISPR collaborations with Intellia, Caribou, applying it in CAR T cell and HSCs), the CRISPR/cas system is the rising star. This system uses a guide RNA to direct the traffic of a single nuclease towards different targets on a chromosome to alter DNA sequence through cutting. The nuclease, cas9, can be mutated from a double-stranded DNA endonuclease to a single-strand cutter or a non-cutting block, or further fused to various functional domains such as a transcription activation domain. This system can also be used to edit RNA molecules.

A weak spot on the sharp blade of CRISPR is, like any methods for creating loss-of-function effects (RNAi if you remember), the potential of off-target effects. While they can never be completely avoided, with the ever growing popularity of deep sequencing, at least we can know all unintended changes on the edited genome. Almost a perfect storm! As an interesting side story, when we at Allele Biotech first saw the paper in Science describing the CIRPSR/cas system [3], we immediately wrote an SBIR grant application for applying the bacterial system to mammalian cells. The first round of review in December 2012 concluded that it would not work due to eukaryotes’ compact chromatin structures. Of course, the flurry of publication in early 2013, while our application was being resubmitted, proved otherwise. The good news is, Allele Biotech still received an SBIR grant from NIGMS in 2014. Unlike most of the genome editing platforms known in the literature, our goal was to build an all-RNA CRISPR/cas system, thereby with higher potency, less off-target effects, and, as a footprint-free platform, more suitable for therapeutic applications. This system will be combined with our strengths in iPSC and stem cell differentiation, fluorescent protein markers, and deep sequencing based bioinformatics to improve cell therapy and cell based assays.

1 Urnov, F.D., et al., Genome editing with engineered zinc finger nucleases. Nat Rev Genet, 2010. 11(9): p. 636-46.

2 Reinhardt, P., et al., Genetic Correction of a LRRK2 Mutation in Human iPSCs Links Parkinsonian Neurodegeneration to ERK-Dependent Changes in Gene Expression. Cell Stem Cell, 2013. 12(3): p. 354-67.

3 Jinek, M., et al., A Programmable Dual-RNA-Guided DNA Endonuclease in Adaptive Bacterial Immunity. Science, 2012.

Path to Better Drugs through Disease-Specific iPSCs

Induced human pluripotent stem cells

The recent finding that pluripotency, the ability to differentiate into all cell types typically associated with embryonic stem cells, can be induced in somatic cells may be the molecular equivalent of the discovery of antibiotics or vaccines in the last century [1].

iPSC-based disease modeling

Recent studies have described the generation of induced pluripotent stem cells (iPSCs) from patients with a full range of genetically inherited or sporadic diseases, and in vitro differentiation of these iPSCs to cell types relevant to the disorder with certain disease features.

Example 1 (out of ~20): Progressive motor neuron loss during differentiation of iPSCs derived from spinal muscular atrophy (SMA) patients, reflecting developmental loss seen in the disease.

Example 2: iPSCs made from RETT syndrome give rise to glutamatergic neurons with fewer synapses than controls, a better treatment was found from a panel of candidates based on this model.

Example 3: Neurons differentiated from iPSCs that have been derived from early or late onset Alzheimer’s disease were shown to display different properties and potential interference points.

The identification of novel pathways or drugs that could prevent disease is the ultimate goal of the iPSC-based disease modeling approach.

Major steps towards efficient iPSC disease modeling

The first hurdle for feasible application of patient-specific disease modeling is to achieve efficient generation of iPSCs from large cohorts of patients quickly and at a low cost while eliminating “clonal variations”. As described in a recent publication [2], the Allele Biotechnology team has shown that human fibroblasts can be converted to stem cells in just over a week, achieving bulk conversion efficiency without any chromosome modifications. The process is also xeno-free and feeder-free, enabling both fundamental scientific research and clinical applications.

The next major advancements required for disease modeling are robust lineage-specific differentiation protocols that provide a large number of desired cells for drug testing and screening. Cardiomyocytes derived from iPSCs have been the best known example of large expansion; other cell types will become available in the near future. Allele Biotechnology has commenced differentiating iPSCs along several lineages using our own iPSCs of superior quality.

With cells of disease-matching tissue types derived from patients’ iPSCs, cell-based assays can be designed and developed using various assay formats. Allele Biotech’s leading capacities in fluorescence and bioluminescence, gene silencing, delivery vehicles and single-domain targeting agents will be of unmatched value to drug discovery partners.

1. Review: Wu, SM and Hochedlinger, K. “Harnessing the potential of induced pluripotent stem cells for regenerative medicine ” 2011, Nature Cell Biology, V13-5, 497-505.

2. Allele Biotech publication: Warren, L., Ni, Y., Wang, J. and Guo, X. “Feeder-Free Derivation of Human Induced Pluripotent Stem Cells with Messenger RNA” 2012, Nature’s Scientific Reports, doi:10.1038/srep00657.

For business development contact:

iPS@allelebiotech.com

858-587-6645

Fax 858-587-6692

www.allelebiotech.com

6404 Nancy Ridge Drive

San Diego, CA 92121

Related products for academic customers: Non-Integrating iPSC Generation Product Line http://www.allelebiotech.com/non-integrating-ipsc-generation/

New Product of the week: 6F mRNA Reprogramming Premix: $995 for 10 reprogramming!

Categories

- Allele Mail Bag

- cGMP

- Customer Feedback

- Fluorescent proteins

- iPSCs and other stem cells

- nAb: Camelid Antibodies, Nanobodies, VHH

- Next Generation Sequencing (NextGen Seq)

- NIH Budget and You

- oligos and cloning

- Open Forum

- RNAi patent landscape

- SBIR and Business issues

- State of Research

- Synthetic biology

- Uncategorized

- Viruses and cells

- You have the power

Archives

- October 2018

- April 2018

- March 2018

- January 2018

- October 2017

- September 2017

- August 2017

- March 2017

- February 2017

- January 2017

- November 2016

- September 2016

- August 2016

- July 2016

- June 2016

- May 2016

- April 2016

- February 2016

- October 2015

- September 2015

- August 2015

- June 2015

- March 2015

- January 2015

- December 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- August 2012

- July 2012

- May 2012

- April 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011

- April 2011

- March 2011

- February 2011

- January 2011

- December 2010

- November 2010

- October 2010

- September 2010

- August 2010

- July 2010

- June 2010

- May 2010

- April 2010

- March 2010

- February 2010

- January 2010

- December 2009

- November 2009

- October 2009

- September 2009

- August 2009

- July 2009

- June 2009

- May 2009

- April 2009

- March 2009

- February 2009

- January 2009

- December 2008

- October 2008

- August 2008

- July 2008