Generation of Human Stem Cells under Good Manufacturing Practice: Facility Update

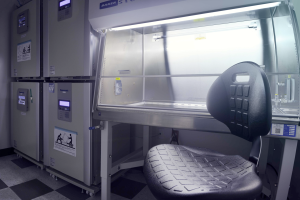

Last year Allele dedicated a new building space for cleanroom operations to provide a cell banking service for personalized medicine. This facility will be the center of current Good Manufacturing Practice (cGMP) production of human induced pluripotent stem cells (iPSCs) using Allele’s proprietary synthetic mRNA platform. Over the past three months, progress to get the facility up and running has been substantial. Our facility includes four main modules: the reception area and doctors’ offices, a Fibroblast Isolation and Maintenance room, a Reprogramming and iPSC Maintenance room, and a Quality Control room. Air handling, which is a major component of the environmental control system, has been installed and validated. Equipment such as biosafety cabinets, incubators, and refrigerators have been installed and qualified, as well as equipment for performing essential quality control steps. To standardize personnel-related steps of cGMP processing, we have prepared rigorous SOPs and have extensively trained individual manufacturing operators. Overall, we are enthusiastic about the facility’s progress and are committed to delivering the best possible service as the industry leader in iPSC banking.

……………………………………………………………………………………………………………………

Making the Most of Microscopy with mNeonGreen

Three years since our flagship fluorescent protein was published in Nature Methods, mNeonGreen is still shining bright. mNeonGreen is a green-yellow fluorescent protein that has been shown to be highly useful in optical assays from general imaging to FRET to super resolution microscopy applications and more.

What makes this fluorescent protein such a hit among researchers?

Since the cloning of green fluorescent protein (GFP) over 20 years ago, fluorescent proteins have become a standard research tool, enabling labeling and imaging of individual proteins within a cell in real time. To make these probes brighter, faster folding, and to cover a wider range of the visible spectrum, new fluorescent proteins are continually being developed. mNeonGreen was engineered by scientists at Allele Biotech from a protein isolated from Branchiostoma lanceolatum, a marine invertebrate, and is the brightest monomeric green-yellow fluorescent protein ever characterized.

Perhaps the most common use of fluorescent proteins today is genetically fusing them to a protein of interest to image protein localization. Unfortunately, many researchers are unaware that many fluorescent proteins – such as GFP – are prone to forming noncovalent dimers, which can lead to significant artifacts. True monomeric fluorescent proteins such as mNeonGreen are less likely to affect the localization, dynamics, or normal behavior when fused to proteins of interest.

For quantitative imaging and live-cell imaging applications, arguably the most critical parameters to consider when choosing fluorescent proteins are brightness and photostability. mNeonGreen has high fluorescence brightness, so less light can be delivered to the cells to collect ample signal intensity, resulting in less phototoxicity. mNeonGreen also has superior photostability, meaning it can undergo many excitation-emission cycles before photobleaching occurs. Because of these properties, mNeonGreen has been shown to be very effective as a fluorophore in fluorescence resonance energy transfer (FRET) – both as an acceptor and a donor.

The community of biologists taking advantage of super-resolution fluorescence microscopy (Nobel Prize in Chemistry 2014) is rapidly growing. But the ability to resolve cellular structural features depends on the chosen fluorophore’s brightness, labeling density, and the stability of the dark state. mNeonGreen is not only extraordinarily bright, but also can be driven into a temporary dark state by light irradiation, making it a useful tag for single-molecule super-resolution imaging of proteins.

Researchers around the world continue to develop novel applications for mNeonGreen. Recently, mNeonGreen was used to create a genetically encoded voltage sensor that can be used to image subcellular changes in electrical activity. Researchers fused mNeonGreen to a light-sensitive ion channel in neurons, linking mNeonGreen fluorescence with the membrane voltage to create an optical readout for neuronal activity with unprecedented speed and accuracy.

Choosing an appropriate fluorescent protein for an assay is often a source of confusion for researchers. In many cases, the selection of a fluorescent protein is motivated by convenience (e.g., availability of the construct) rather than its performance for a given assay. If mNeonGreen seems like the right fluorescent protein for your assay, we at Allele Biotech have made it easy and painless for researchers to get their hands on it. Laboratories can license mNeonGreen for full use at a low cost.

Questions about licensing or whether mNeonGreen is really right for your lab? Contact fp@allelebiotech.com.

References:

“A bright monomeric green fluorescent protein derived from Branchiostoma lanceolatum.”

Shaner, N. C., Lambert, G. G., Chammas, A., Ni, Y., Cranfill, P. J., Baird, M. A., Sell, B.R., Allen, J.R., Day, R.N., Davidson, M.W., Wang, J.

2013 Nat Methods, 10(5), 407-409. doi:10.1038/nmeth.2413

“High-speed recording of neural spikes in awake mice and flies with a fluorescent voltage sensor.”

Gong, Y., Huang, C., Li, J. Z., Grewe, B. F., Zhang, Y., Eismann, S., & Schnitzer, M. J.

2015 Science, 350(6266), 1361-1366. doi:10.1126/science.aab0810

cGMP Compliance: What Does It Mean for Your Cell Lines?

As the promise for cell-based therapy grows, the interest in making clinically relevant cell lines has skyrocketed for industrial and academic researchers alike. For translation into human therapies, cell-based products must be made following current Good Manufacturing Practice (cGMP). Many groups have already claimed to generate cell lines that are “cGMP-compliant,” “cGMP-ready,” or “certifiable under cGMP.” But what does it take to be truly cGMP-compliant, and what practices can you introduce in your lab to comply with cGMP standards?

A common misconception in the United States is that a facility is granted a ‘cGMP license’ from the government to manufacture cGMP-grade products. Rather, the Food and Drug Administration (FDA) evaluates the manufacturing process for each product to determine if it is compliant with cGMP standards. The primary concern when it comes to deriving cell-based products for therapies is making sure that the product is derived in a safe and reproducible manner. To ensure maximum quality assurance, researchers should

• choose reliable, xenogeneic-free raw materials,

• establish and monitor a clean environment,

• qualify all equipment and software,

• remove variation in laboratory procedures by creating detailed Standard Operating Procedures (SOPs) and by providing rigid process validation at each step.

Nevertheless, even establishing robust quality assurance does not imply that the process is scalable for commercial production. In the world of biologics, “the product is the process.” A requisite step to ensure a smooth transition to cGMP practice is to ensure that the process of manufacturing is not altered due to changes in production scale. For example, depending on the therapy, millions or billions of cells may be required for a single patient. Therefore, it is in the best interest of the researchers to develop a scalable method at the beginning to avoid revamping the entire process (e.g., changing from adherent cells to suspension). Along these lines, the quality control (QC) requirements of cell-based products should be carefully considered and not have to include difficult-to-assay tests. For example, some cell lines have been qualified as cGMP-compliant upon conversion from research-grade conditions to cGMP quality standards. Rigorous tests were performed on the converted lines to ensure that the cells were free of contamination. Even though strict measures were carried out to ensure cGMP compliancy, deriving cell lines in this manner makes scalability and reproducibility a challenge. Ideally, the entire process of deriving cell products for clinical use should be performed under cGMP conditions: from the acquisition of human tissue to the manufacturing, testing, and storage of derivative cell products.

Another important consideration when instituting cGMP-compliance is documentation. Each process must be described with rigorous SOPs, the training of individual manufacturing operators must be well-documented, and the entire established process must be validated and well noted. Failure to document—in the eyes of the FDA—is often equated with failure to perform the underlying activity. It is equally important to remain ‘current.’ The FDA expects manufacturing processes to stay up-to-date with current regulations, even as policies change.

For an academic lab, closely aligning with cGMP standards can ensure that the resulting cell lines are comparable to other truly cGMP-produced products used during clinical trials. It is in the best interest of academic researchers to establish rigorous SOPs and use qualified reagents and equipment, even if it is not possible to carry out all steps in a certified cleanroom. Whenever possible, it is advisable to acquire truly cGMP cell lines from appropriate sources for preclinical projects; if prohibited by costs or other reasons, it is recommended to use a protocol that is as close to cGMP as possible.

Researchers use GFP nano antibody to study organ growth

Single-domain nano antibodies have a broad range of applications in biochemistry due to their small size, high affinity, and high specificity. Now, a team of researchers from the University of Basel and the University of Zurich has demonstrated that nano antibodies can be used for research in complex living organisms such as Drosophila, uncovering another new and exciting application for nano antibodies.

The team used nano antibodies to develop an assay for studying morphogens, molecules that regulate the pattern of tissue growth and the positions of various cell types within tissue. Morphogens form long-range concentration gradients from a localized source, ultimately determining the fate and arrangement of cells that respond to that gradient. Drosophila is a classic model system for understanding how morphogens regulate organ development. One morphogen called Dpp controls uniform proliferation and growth of the wing imaginal disc. Yet because Dpp is an extracellular, diffusible protein, it is difficult to immobilize in situ. Therefore, despite over 20 years of studying the role of Dpp as a morphogen, the lack of a dynamic system for controlling Dpp gradients has prevented researchers from understanding precisely how Dpp governs development of the wing disc.

By developing a novel synthetic system using nano antibodies, the researchers were able to modulate the concentration gradient of Dpp at the protein level. Their system—coined “morphotrap”—uses a membrane-bound GFP nano antibody to “trap” GFP-tagged Dpp at different locations along the wing imaginal disc. By tethering Dpp in a controlled spatial manner, researchers were able to determine how Dpp gradients affect wing disc development. They discovered that the gradient of Dpp is required for the patterning of the wing disc but not for lateral growth, disproving one of the field’s popular theories that address the role of Dpp. In addition to resolving the controversy with respect to the role of Dpp as a morphogen, this study pioneers a new method for using nano antibodies in situ.

“Dpp spreading is required for medial but not for lateral wing disc growth.”

Harmansa S., Hamaratoglu F., Affolter M., Caussinus E.

Nature. 2015 Nov 19;527(7578):317-22. doi: 10.1038/nature15712. Epub 2015 Nov 9.

Allele Biotechnology & Pharmaceuticals Forming Cell Banking Business for Personalized Medicine

Allele to Generate Human iPS Cells under Good Manufacturing Practice for Private Individuals for Potential Therapeutic Use and Future diagnostics; Cell Banking Scientific Advisory Board formed

October 06, 2015 11:25 AM Eastern Daylight Time

SAN DIEGO–(BUSINESS WIRE)–Allele Biotechnology & Pharmaceuticals, Inc. (“Allele”), a leader in the development of specialized cells for regenerative medicine and pharmaceutical drug discovery, today announced plans to form a commercial business for the banking of human induced pluripotent stem cells (iPSCs) by private individuals.

Allele is pleased to have Drs. Mahendra Rao and Joseph Paulauskis as the first members of its Scientific Advisory Board (SAB) for iPSC banking and cGMP production. Dr. Rao is a world-renowned scientist in the fields of stem cells and medicine, having served as the VP of Regenerative Medicine at Invitrogen, founding Director of the NIH Center for Regenerative Medicine, Chair of the Biological Response Modifiers Committee (BRMAC, now CTAGT) of the FDA, and he is currently Chief Strategy Officer at Q Therapeutics. Dr. Paulauskis is the Chief Operating Officer of Paradigm Dx as well as the Vice-President of Research and Biobanking for the International Genomics Consortium, and has previously held senior positions in pharmacogenomics at Pfizer. Allele plans to make additional appointments to the SAB as individuals with world-class experience and expertise are identified.

Human iPSCs are cells that can be grown to virtually infinite numbers and can become any cell in the human body, features which hold great promise for therapies that can alleviate or cure human disease. Allele’s business model recognizes that an individual can have their own cells ready for future therapeutic use via the generation and storage of iPSCs from that individual’s skin cells. While this is similar to what is done with newborn cord blood, iPSCs can be generated from humans of any age. The banking of human iPSCs for potential future therapeutic use is a relatively new industry with unprecedented potential, and Allele is benefitting from expert opinions internally and from current and future SAB members, ensuring a solid scientific and ethical foundation for this business.

In addition to serving its customers, Allele’s iPSC bank will be an unparalleled resource for biomedical research. Proper consent and privacy guardianship will allow thousands of iPSC lines with accompanying sequence database and health information to be made available from the bank to scientists and clinicians. Currently, iPSC banks are funded by government agencies at multi-million dollar costs per project; Allele’s model does not rely on tax dollars and provides potentially a larger bank of iPSCs of higher quality to aid research and treatment efforts. To this end, NIH Director Dr. Francis Collins recently announced the implementation of the Precision Medicine Initiative (PMI), the goal of which is for health care professionals to have the resources to take into account individual differences in genes, environments, and lifestyles that contribute to disease when providing treatments in the new era.

“We are happy to have the guidance from world leading experts in stem cells, biobanking, and cell therapy fields such as Drs. Rao and Paulauskis”, said Jiwu Wang Ph.D., President and CEO of Allele. “We believe that setting the bar high will be ultimately beneficial to future customers, fellow researchers, industry partners, and regulatory agencies alike. We are happy to see the recent release by the International Society for Stem Cell Research of a draft of ‘Guidelines for the Clinical Translation of Stem Cells’, whose principals we plan to follow closely. We also intend to obtain certification by the cord blood banking association AABB, if possible, and abide by other regulatory rules as they become public, such as the “Stem Cell Clinical Research Management (tentative)” by the Health Commission of China, if and when we move to operate under that jurisdiction”.

Towards the establishment of this business effort, Allele has recently purchased an 18,000 square-foot facility, located near its headquarters in San Diego, California. This new facility will be the center of cGMP-production of human iPSCs using Allele’s proprietary synthetic mRNA platform, a technology that generates cells with neither the random integration of foreign DNA nor the use of viruses or virus-based elements, drawbacks common to other technologies for making hiPSCs; thus, the “footprint-free” cells generated by Allele’s synthetic mRNA platform are optimally suited for therapeutic use, and Allele’s technology has been licensed for clinical trials by companies such as Ocata Therapeutics (formerly ACT). This effort received strong support from Yuan Capital and Yifang Ventures.

About Allele Biotechnology & Pharmaceuticals, Inc.

Allele Biotechnology and Pharmaceuticals, Inc. is a private, San Diego-based company that explores the mechanisms of biological processes to develop technologies and products for biomedical researchers. Allele utilizes proprietary non-integrating cellular reprogramming methods to generate human and non-human primate iPS cells, GMP-grade human iPS cells and their derivatives, and differentiated cell types. With additional expertise in genome modification and cell-based sensors/reporters, Allele provides advanced cell-based assays for drug discovery. Allele also has developed a wide variety of reagents including superior fluorescent proteins and camelid antibodies. The company has also been a leader in the RNAi field with its patents in Pol III promoter-driven siRNA, shRNA, and miRNA.

Contacts

Allele Biotechnology & Pharmaceuticals, Inc.

Matthew A. Singer, Ph. D.

Director of Business Development and Strategic Alliances

+1 858-587-6645, ext. 1

mattsinger@allelebiotech.com

www.allelebiotech.com

Categories

- Allele Mail Bag

- cGMP

- Customer Feedback

- Fluorescent proteins

- iPSCs and other stem cells

- nAb: Camelid Antibodies, Nanobodies, VHH

- Next Generation Sequencing (NextGen Seq)

- NIH Budget and You

- oligos and cloning

- Open Forum

- RNAi patent landscape

- SBIR and Business issues

- State of Research

- Synthetic biology

- Uncategorized

- Viruses and cells

- You have the power

Archives

- October 2018

- April 2018

- March 2018

- January 2018

- October 2017

- September 2017

- August 2017

- March 2017

- February 2017

- January 2017

- November 2016

- September 2016

- August 2016

- July 2016

- June 2016

- May 2016

- April 2016

- February 2016

- October 2015

- September 2015

- August 2015

- June 2015

- March 2015

- January 2015

- December 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- August 2012

- July 2012

- May 2012

- April 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011

- April 2011

- March 2011

- February 2011

- January 2011

- December 2010

- November 2010

- October 2010

- September 2010

- August 2010

- July 2010

- June 2010

- May 2010

- April 2010

- March 2010

- February 2010

- January 2010

- December 2009

- November 2009

- October 2009

- September 2009

- August 2009

- July 2009

- June 2009

- May 2009

- April 2009

- March 2009

- February 2009

- January 2009

- December 2008

- October 2008

- August 2008

- July 2008